Automatic Welded Wire Mesh Machine

Description :

The raw material is suit for low-carbon wire, galvanized wire, stainless steel wire etc.

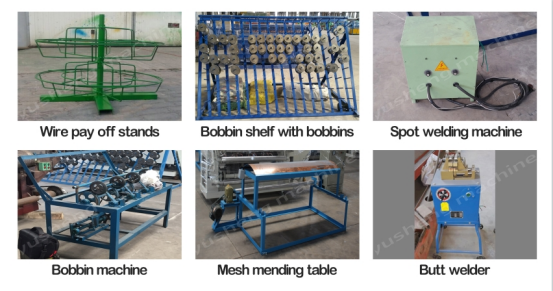

The production line consists of main mesh welding machine, electrical control cabinet, repairing machine, repairing table, bobbin machine, bobbins, bracket for longitude wires, wire pay off stand.

Advantage:

Both longitude wire and cross wire can be feeded from wire coils automatically. It also have the advantage such as design reasonable, low noise, more stable, easy operation and electro-magnetism adjustable speed for welding. The mesh size is precise and the machine can be set the mesh width and mesh length according to customer’s requirement.

Technique details as flows:

Item | DHWJ-1 | DHWJ-2 | DHWJ-3 | DHWJ-4 | DHWJ-5 | DHWJ-6 |

Wire Diameter(MM) | 0.5-0.8 | 0.8-1.2 | 0.8-1.8 | 0.8-2.0 | 1.2-2.5 | 1.5-2.8 |

Mesh Size | 1/4''-2'' | 1/2''-2'' | 1/2''-4'' | 1''-6'' | 2''-6'' | 2''-6'' |

Net Width(M) | 3feet,4feet | 4feet,5feet | 4feet,5feet,6feet | 4feet,5feet,6feet | 5feet,6feet,7feet,8feet | 5feet,6feet,7feet,8feet |

Motor Power(KW) | 3.0 | 3.0 | 3.0 | 4 | 6 | 6 |

Max Speed(rows/mim) | 75 | 100 | 120 | 80 | 75 | 80 |

Usage:

The finished welded wire mesh widely used in mining, commerce, transportation, construction (walls with nets, floor heating network), decorating, landscaping protection, all sectors of the fence, concrete roads, airport runways, tunnels, bridges, pipelines communication, water conservancy, power plant, dam, harbor, river beware wall, warehouses and other types of construction of the reinforced concrete structure with a net.

Accessories for choice :